Today’s economic and political climate adds new challenges to the existing need to protect people, assets and the community. In such a scenario, the oil and gas industry commands a lot of influence, based on its power to impact almost every other commodity in the market. Therefore, it becomes imperative to be able to identify risk and solutions through technological innovations to maintain global economic balance and need.

Tightening risk tolerance and the introduction of more stringent health, regulatory and environmental licensing requirements put a greater focus on oil plant safety. Upstream operations are characterized by complexity and high risks. Despite the fast pace of technological advancement, the

According to an Oil & Gas IQ survey of CIOs, IT Directors, and project leaders in the industry, the number 2 priority for CIOs in 2013 was mobile technology. To add to that, 55% of CIOs believe that mobile technology will greatly enhance operations. Hence it will become of utmost significance for mobile technology to be implemented. Mobility comes with the capacity to inject efficiency and effectiveness in the safety process by providing a framework for information dissemination, advanced analytics (simulation), access to database, communication with and mobilization of the right experts and teams, among other factors.

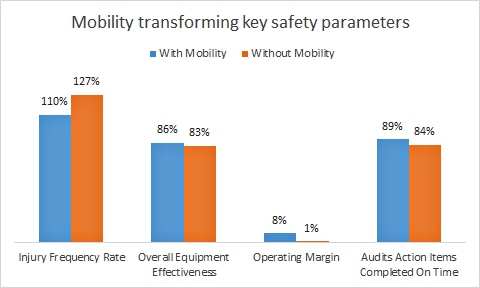

This indicates that the companies are leveraging mobility in transforming the safety division and have been able to reduce the accidents, improve the Overall Equipment Effectiveness (OEE), as well as ensure higher compliance of the Audit action items thereby translating into higher Operating margin.

· In the domain of plant audit, mobility could enhance the effectiveness of a manual data capture system by improving the data accuracy, consistency, and availability of information. Video and image recordings of the safety breach at the incident can be stored and shared seamlessly.

· Mobile solutions can reduce human error by enforcing procedural integrity for human activity, effectively closing the loop around the “stranded” assets that traditional monitoring misses. Wireless-enabled PDAs, tablet PCs and other mobile technologies combine wireless technology with a managed workflow that can validate and track the completion of human-based activities. Regulatory procedures, inspections and other activities can also be logged and monitored on the mobile.

· Mobility could inject efficiency in the system and process of recording events, which are manually maintained and monitored in old and non-digitized oil fields. The structured/unstructured data can be easily integrated with other electronic systems, facilitating the systematic recording of events from other systems, and supporting a faster rule-based interpretation/evaluation of the overall plant condition.

· Workflow management is another area that can expedite the entire process of managing the safety event. The operator can prepare the safety report with the details of the incident and send to the technical team for validation and support. The safety head can then access the information via mobile to approve a plan of action with subsequent dissemination of the information to all those concerned. All this can be integrated with the Document Management System on mobility platform.

Mobility presents an opportunity to provide contextual displays by splitting the plant into safety zones. Alerts can be sent over a mobile platform based on rule-based threshold limits to the right individuals with details about problem. Based on the alert, various department SMEs like Field Technicians, Operators and Maintenance Supervisors can take appropriate action to resolve the threat. This is where the power of Cognitive Decision-Making Science could be leveraged to create a Knowledge Organization. Engineers will be able to scale knowledge and expertise to surface evidence weighted insights from the knowledge repositories (internal and external) to create a fast learning organization to enhance drawing insights for Safety Event. Field Operators will be able to ask complex natural language questions for evidence weighted answers to their common issues from the knowledge repository using Cognitive Computing and be able to fix the problem in the least possible time.

Although one can implement any of the above solutions independently, the best way to ensure cost-effective sustainable safety over the long-term is by committing to a comprehensive safety program. Mobile technologies have a great potential to redefine and re‐engineer the conventional setting for safety management of Oil and Gas assets by offering advanced and smart solutions to remotely manage complex, high‐risk, and capital‐intensive assets regardless of the geographical location, thereby building agile information.

(The author is a Sr. Managing Consultant at IBM India)